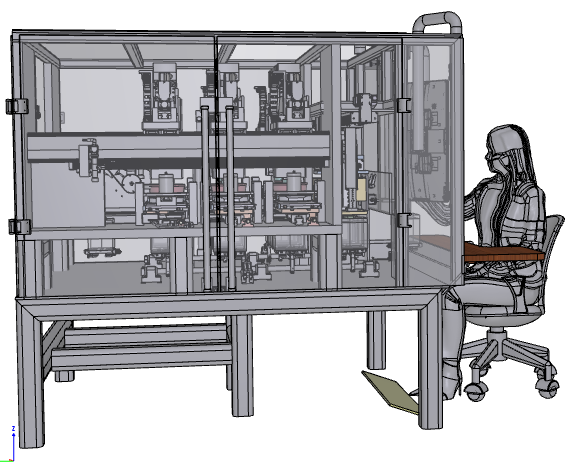

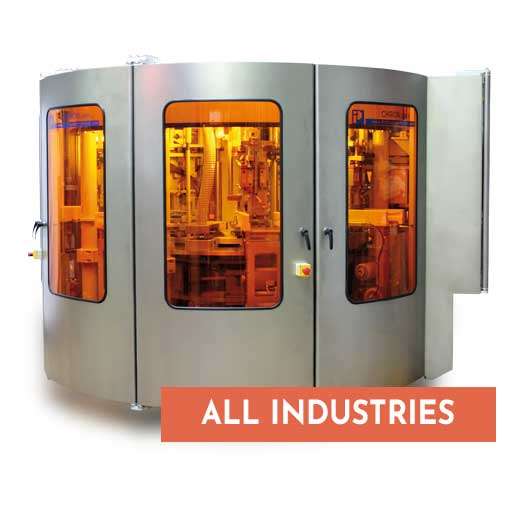

KRATOS

HIGH PRECISION/SHORT SET-UP TIME

The KRATOS is a fully customizable NEXT GENERATION pad printing machine for every industry. Using our patented technology, it achieves the highest print accuracy with the shortest set-up times and ensures quick and easy switching between images and products. Centralized recipe management for the fleet of machines allows for consistent and identical printing across multiple machines, regardless of their physical location. This ensures that the quality of the printed product remains the same, regardless of where it is produced.

ACR Module: automatic SetUp in few seconds, highest print accuracy, quick changeover

Camera inspection: print, assembly, orientation, tray full/empty.

Automatic feeding: hopper, vibrating bowl, linear vibration, rotary table.

Reporting: machine KPI, batch sampling.

Product handling: jig, vacuum, …

Pre-treatment: hot/cold air, plasma, flame, corona, UV, ionisation.

Automatic pad cleaning

Post-treatment: IR, NIR, hot air.

Assembly

Rejection: individual, batch, product samples.

HMI remote position

Product transport: rotary table, LTS shuttle, linear shuttle, belt driven indexer.

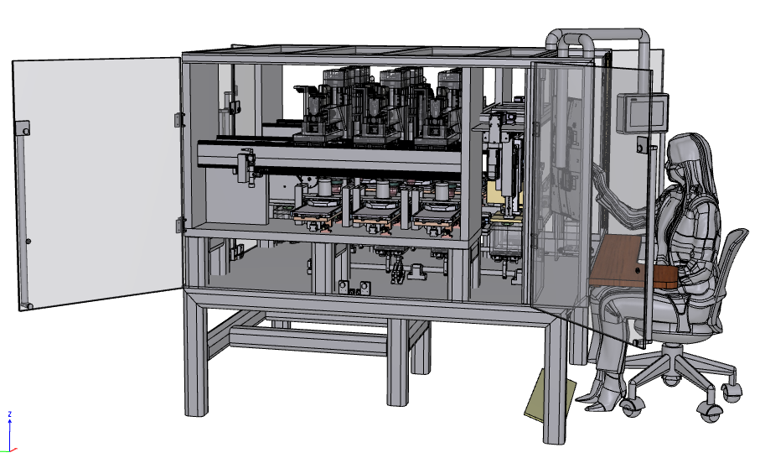

ROTA

The ROTA setup is used when the number of working stations is limited and it is important to have good accessibility to all parts of the machine. By placing the working stations outside of the product trajectory each module can easily be reached by hand during production.

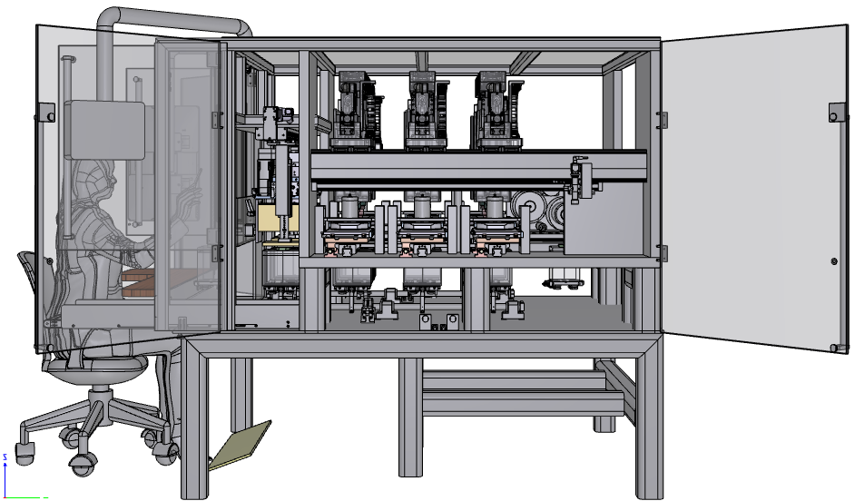

LINO

The LINO setup is used to maximize the number of working stations. By placing it in a line it is possible to add feature after feature. This setup also allows great accessibility from all sides.

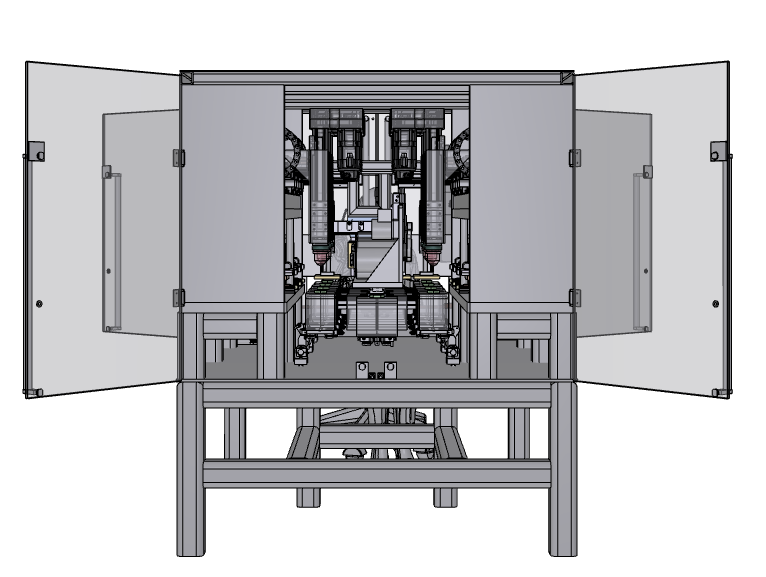

RING

The RING setup is used when production space is limited and machine design needs to be as compact as possible. By placing all working stations inside the product trajectory we save a lot of space, but it also makes it harder to access certain parts during production.

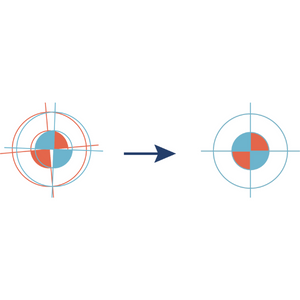

Highest print precision

Siemens OEM Partner

Fast change-over

Compliant to

Download technical sheet

Please fill in your contact details