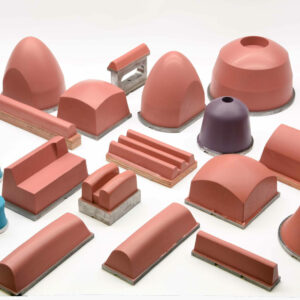

pad printing pad

The function of a pad printing pad is simple: a pad printing pad is the ink transfer mechanism in pad printing machine, the pad picks up the ink (image) and transfers it to the product. A pad is a three-dimensional object moulded of silicone rubber. Pad printing pads vary in shape and diameter depending on the application. It is very important to choose the right pad printing pad and use it in the right way so a good print quality can be achieved. The type of silicone and hardness (shore A) of the pad printing pad depends upon the application. Continue reading to find the right pad for your pad printer.

+2000 DIFFERENT PADS

Over the years we accumulated all the pads we ever sold, in the meanwhile we manage a database of over +2000 different pad printing pads. So we can say we have the expertise to make good pad printing pads.

ALL SHAPES AND SIZES

The size of the pad printing pad depends on the image that needs to be printed on the product. Otherwise, the pad printing pads can be divided into 4 shapes: square – rectangular – roof-shaped – conical

VALIDATIONS

We offer pad printing pads with food-graded and FDA approved certifications. This can be necessary for industries such as: pharmaceutical, medical device or the food industry.

FAQ

What determines the pad quality?

The smoothness of the surface is a decisive factor in the quality of the print. The smallest impurities or air bubbles caused by defects in manufacturing result in unclear print. In the beginning, new pad printing pads tend not to pick the ink up from the printing plate as well. This problem can be solved by making a few prints on paper or by a short cleaning operation using alcohol. If cleaned with aggressive agents, such as thinner, the pad immediately takes the ink from the printing plate, but does not transfer it to the product to be printed quite as well. Once a pad printing pad is “broken in”, it is recommendable to clean the pad surface with an adhesive tape to remove any dust particles.

There are two standard types of silicone pad printing pads:

- red: for machines with a high capacity and in particular for printing on objects with smooth surfaces. These tampons are suitable for pharmaceutical applications (FDA approved) and are available with a certificate.

- blue: these pad printing pads have the same quality as the red ones, but are anti-static.

What is the life expectancy of a pad?

Wear and tear are common, when using a product non-stop. The pad printing pad is one of the components of the pad printing supplies that must be changed regularly to ensure you are getting a solid print. One pad printing pad can be used to print approximately 50,000 to 100,000 products. This, however, depends on the quality of print required and the type of inks used. The life expectancy is longer using single-component inks and shorter using two- component inks. The size and shape of the pad printing pad as well as the shape of the material printed also has an influence on the life expectancy. In the case of very sharp corners or extreme curvatures on an object to be printed, the pad can be physically damaged after as few as 1,000 to 5,000 prints. The physical properties, such as tear resistance or resistance to swelling in contact with solvents are better with a harder pad printing pad compared to a softer one; The softer pad contains more oil, which will have a bad influence on the physical properties.

The life expectancy of a pad printing pad can be extended considerably by careful cleaning and treatment with silicone oil. To extend the lifetime of a pad printing pad, we recommend using a pad no longer than 8 hours in succession. After eight hours of production, it must recover for eight hours. Before the pad printing pad is stored, it must be treated with pad printing oil.

When do you need to change the pad?

When picking up the image from the printing plate, the pad printing pad will absorb a very small amount of the ink mixture (ink, solvent and hardener). Over time, the pad printing ink hardeners in the ink will break down the material of the pad printing pad. Resulting in a smoother top to the pad and an overall discoloration of the pad. The most important reason to change your pad printing pad is to ensure the best print quality. Technicians will spend hours trying to find a “good” spot on an old pad printing pad when in reality, purchasing a new one is easier and saves time. We also recommend to keep a stock of pad printing pads in your production facility. Don’t try to use the same pad for different images- they all pick up ink on different parts of the pad.

Tampon-related problems during pad printing

PAD DOES NOT TAKE UP INK / OR ONLY PARTIALLY?

PAD DOES NOT RELEASE INK / OR ONLY PARTIALLY?

Other problems?

Download the Troubleshooting guide from the pad printing experts of Printing International with the most common problems and solutions hier

What is the best way to store a pad?

Here then the three rules for storing a pad printing pad:

- A pad must be stored on its base. The pad printing pad should not be directly exposed to the light, including excessive heat or cold.

- Pad printing pads may never be stacked one above the other. Placing the pads on top of each other can cause the pad to become deformed.

- A pad printing pad must be kept clean, it must never be stored if when there is still ink on the surface of the pad. It is not recommended to clean the pad printing pad with solvents. Use pad print cleaner.

Download THE BROCHURE

Please fill in your contact details